Protective gloves, hand protection – Effective protection for fine motor to heavy-duty tasks

Feeling, gripping, creating – our hands are a brilliant all-purpose tool. Without protection, they are constantly exposed to dangers and are the most commonly injured body part in accidents: Hands are involved in nearly 40 percent of all workplace accidents. That’s why the right protective gloves are so important.

To the productsWhat materials are available and how do they differ?

What coatings are available and how do they differ?

What is the Gauge number?

The Gauge number refers to the number of stitches per inch (1 inch = 2.54 cm). The higher this number, the finer the gloves are, as a finer yarn is used. The finer the glove, the higher the dexterity and tactile feel.

- 7 Gauge: Coarse knit

- 10 Gauge: Medium knit

- 13 Gauge: Fine knit

- 15 Gauge: Fine knit

- 18 Gauge: Fine knit

What does OEKO-TEX Standard 100 mean?

OEKO-TEX Standard 100 is one of the most well-known labels for tested textiles (e.g., protective gloves, as well as work and protective clothing). If a textile item is labeled with the OEKO-TEX Standard 100, you can be sure that all components, such as threads and buttons, have been tested for harmful substances.

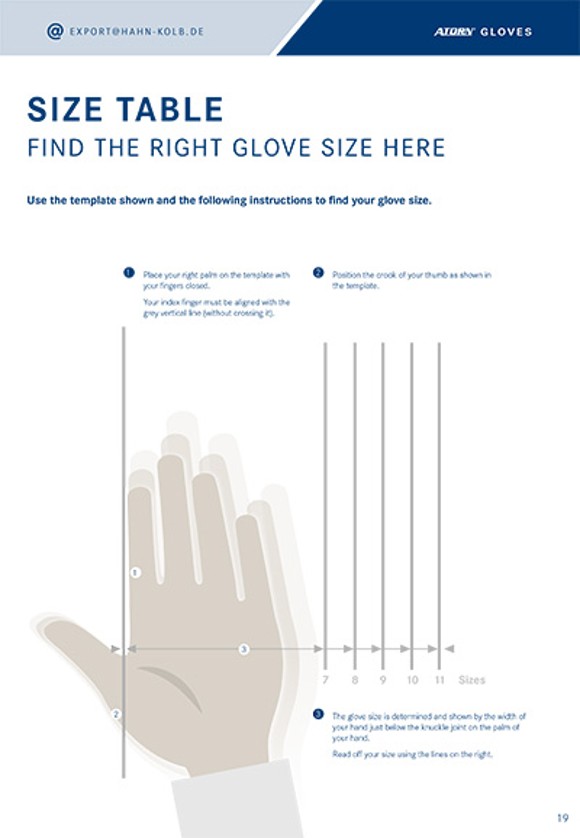

How do I find the right glove size?

With our size chart, you can easily find the right glove size for your hands. Simply print our size chart with the template in A4 and follow the instructions.

Print now.What standards exist in the field of hand protection?

Guide for Pictograms and Technical Terms

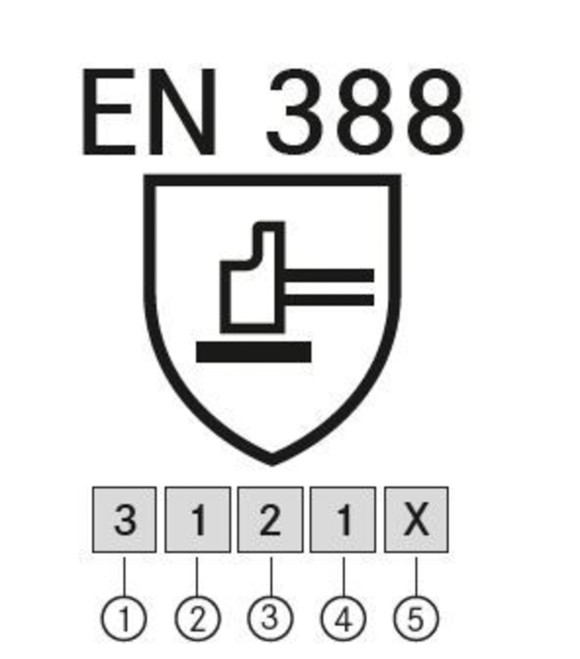

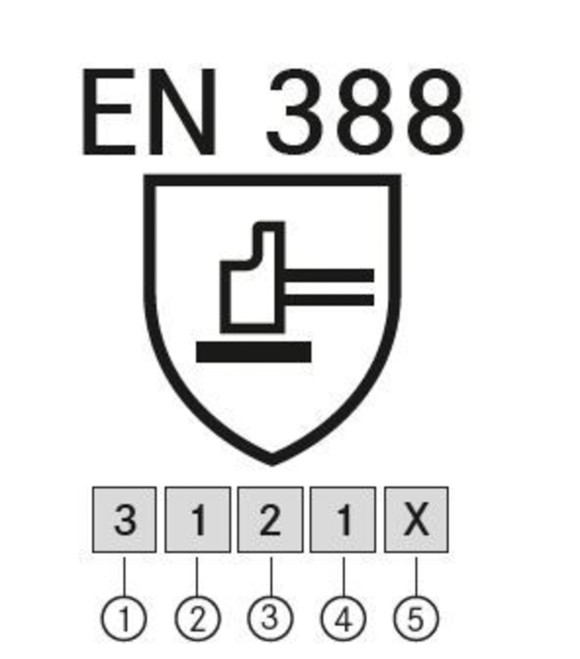

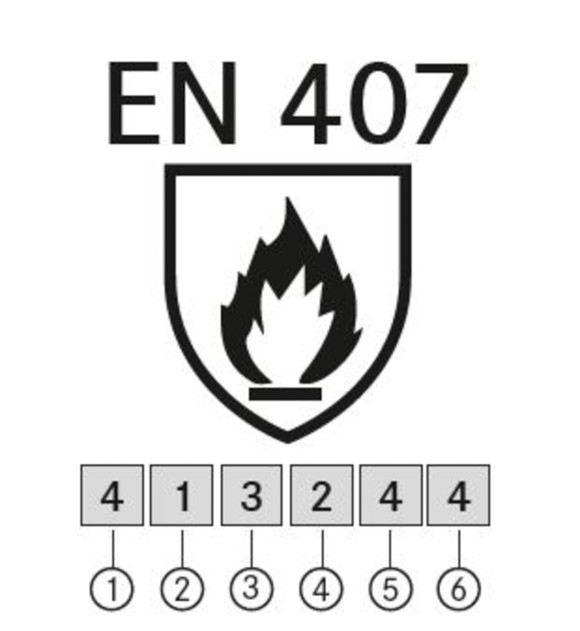

The number below each pictogram represents the performance level that the respective glove meets – depending on the standard, these are either numbers or letters. For the numbers: the higher the number, the better the protective function. If an "x" appears instead of a number in the row, the glove is not suitable for the respective application.

Requirements for Protective Gloves according to ISO 21420

ISO 21420 establishes the general requirements and testing procedures for protective gloves. Among other things, it ensures that the materials used, the processing of fabrics and seams, and all parts of the glove that come into direct contact with the wearer must not adversely affect their health. Additionally, protective gloves according to ISO 21420 must be labeled with a range of information: the manufacturer and the product must be clearly identifiable. A size label and, if applicable, an expiration date must also be indicated.

Protection against mechanical risks – EN 388:2016

Gloves that meet high requirements for mechanical resistance, abrasion, puncture, and cut resistance.

| Test Criterion | Performance Level |

| ① Abrasion Resistance | 0-4 |

| ② Cut Resistance | 0-5 |

| ③ Tear Resistance | 0-4 |

| ④ Puncture Resistance | 0-4 |

| ⑤ Cut Resistance according to ISO 13997 | A-F |

Protection against chemical and biological risks – EN ISO 374-1:2016

EN ISO 374:2016 divides chemical protective gloves into three types: Type A, Type B, and Type C. Type C does not have any letters under the pictogram.

| Type | Label | Permeation Time / Test Chemicals |

| A | EN ISO 374-1/Type A | ≥30 min / 6 chemicals |

| B | EN ISO 374-1/Type B | ≥30 min / 3 chemicals |

| C | EN ISO 374-1/Type C | ≥10 min / 1 chemical |

| Test Chemical | Substance Class | |

| A | Methanol | Primary alcohols |

| B | Acetone | Ketones |

| C | Acetonitrile | Nitrile compounds |

| D | Dichloromethane | Chlorinated hydrocarbons |

| E | Carbon disulfide | Sulfur with organic compound components |

| F | Toluene | Aromatic hydrocarbons |

| G | Diethylamine | Amines |

| H | Tetrahydrofuran | Heterocyclic and ether compounds |

| I | Ethyl acetate | Esters |

| J | N-Heptane | Saturated hydrocarbons |

| K | Sodium hydroxide 40% | Inorganic bases |

| L | Sulfuric acid 96% | Inorganic mineral acids, oxidizing |

| M | Nitric acid 65% | Inorganic mineral acids, oxidizing |

| N | Acetic acid 99% | Organic acids |

| O | Ammonia 25% | Organic base |

| P | Hydrogen peroxide 30% | Peroxide |

| S | Hydrofluoric acid 40% | Inorganic mineral acid |

| T | Formaldehyde 37% | Aldehyde |

Protection against microorganisms (bacteria and fungi) – EN ISO 374-5:2016

Gloves for protection against microorganisms, such as bacteria and fungi. The designation VIRUS indicates additional protection against viruses.

Protection against heat – EN 407

Gloves that meet high requirements for heat or flame protection.

| Protection against... | Level |

| ① Ignition | 0-4 |

| ② Contact heat | 0-4 |

| ③ Convective heat | 0-4 |

| ④ Radiant heat | 0-4 |

| ⑤ Small splashes of molten metal | 0-4 |

| ⑥ Large quantities of liquid metal | 0-4 |

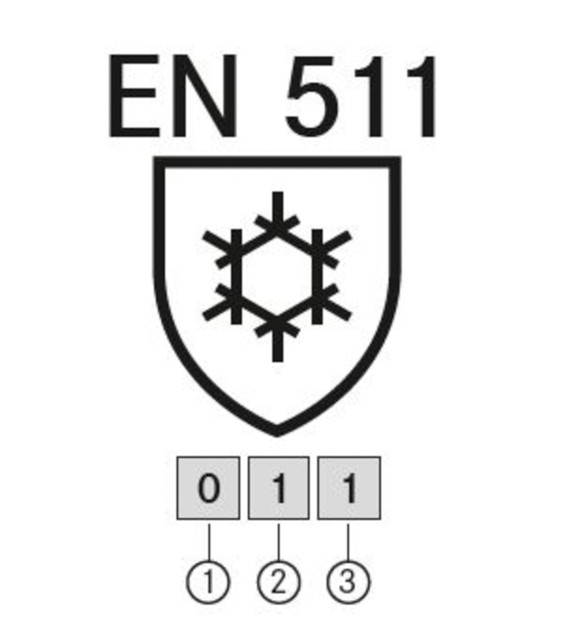

Protection against cold – EN 511

Gloves that protect against both contact cold (upon touch) and penetrating cold (convective cold).

| Property | Level |

| ① Convective cold resistance | 0-4 |

| ② Contact cold resistance | 0-4 |

| ③ Water resistance (1 - at least 30 minutes waterproof) | 0 or 1 |

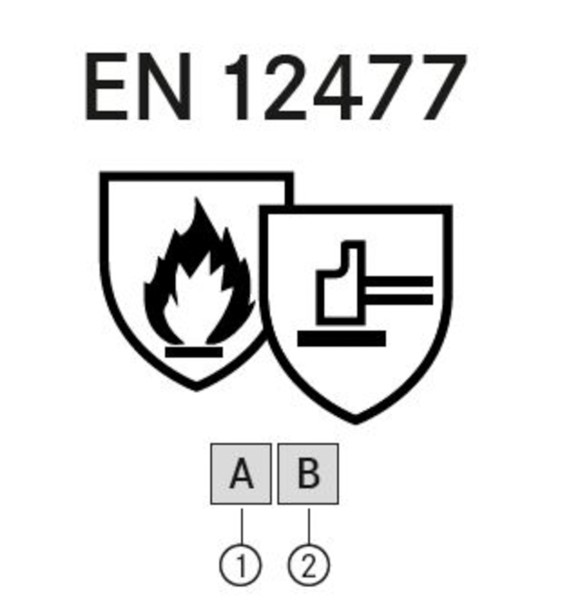

Welding protection

The mechanical and thermal resistance of the gloves are tested according to the criteria of EN 388 and EN 407. There are two performance classes: Type A and Type B.

| Type | Property |

| ① Type A | Low dexterity with high other requirements |

| ② Type B | High dexterity with low other requirements |

Did you know that we have ATORN gloves in our range?

Whether in assembly areas or with cutting hazard risks, ATORN protective gloves offer the perfect fit, the highest quality, and maximum performance for daily use. Gloves – anyone can do that. But performance and quality – only ATORN can deliver that.

Discover ATORN gloves