Disc Brushes – Efficiency through Innovation: ATORN Disc Brushes with High-Tech Bristles

Maximum Bristle Density - Minimum Process Costs

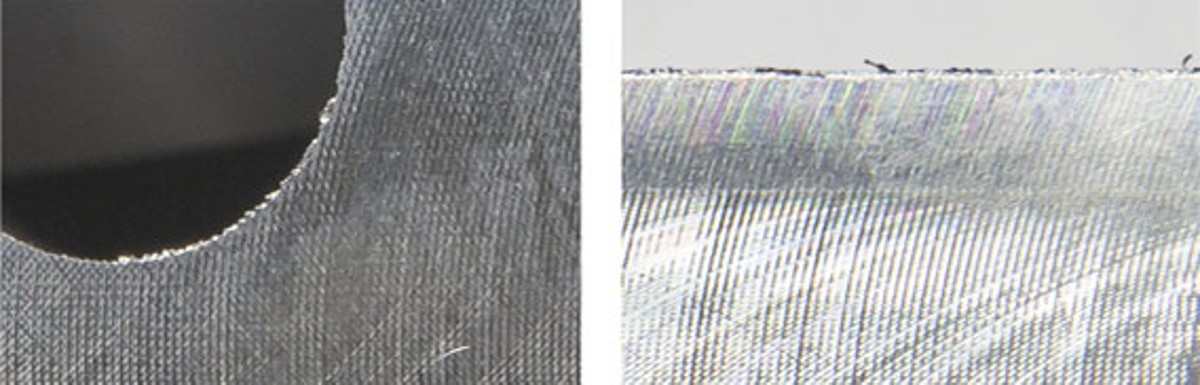

The primary application of ATORN Disc Brushes is in precise deburring, edge rounding, and surface finishing of precision parts without altering the geometry of the workpiece.

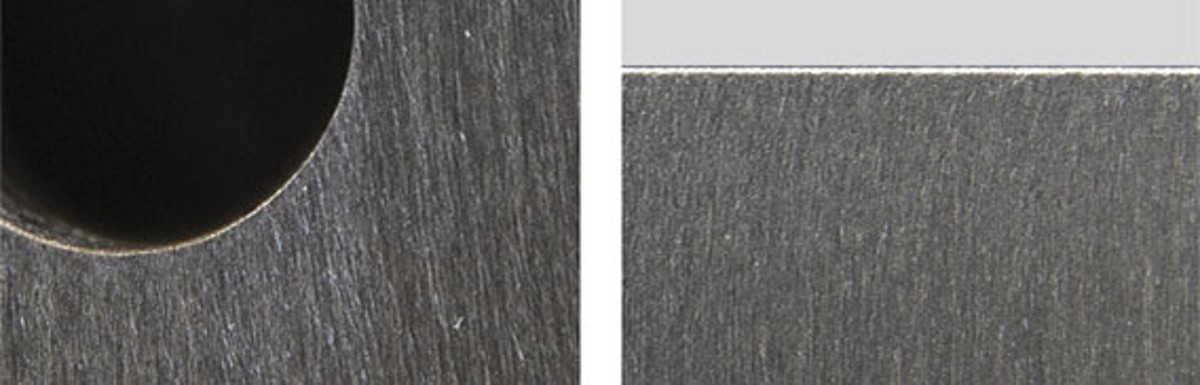

ATORN Disc Brushes have four times the bristle density compared to traditional (stamped) disc brushes.

As a result, the brush lifespan is significantly extended, while simultaneously achieving higher feed rates and better, more efficient deburring results.

To the productsHigh-Tech Bristles

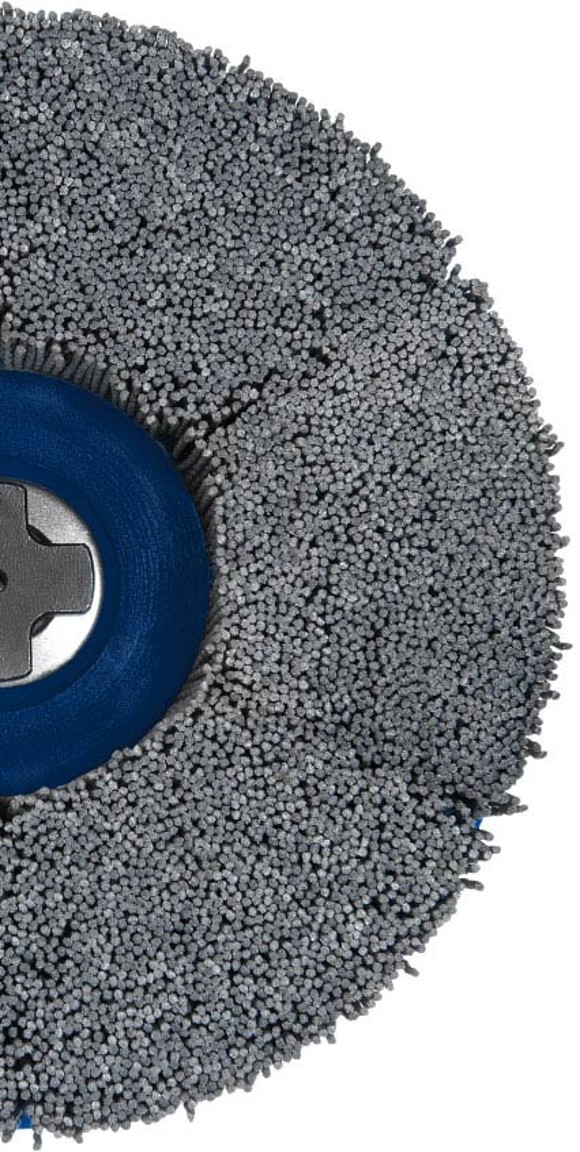

- High abrasive grain content for effective deburring

- Use with coolant possible/recommended

- Customizable for each material to be processed

- Highly wear-resistant abrasive bristles with excellent reconditioning capability

- Flat bristle surface

- Aggressive brushing action

Thoughtful Design

- Standardized tool head and combination spindle mounting

- High form stability and roundness accuracy

- Firmly cast bristles

- Extremely dense bristle surface

Direct Mounting on Combination Milling Spindle / Tool Head

The ATORN Disc Brushes are designed for direct adaptation to tool holders with a combination milling spindle mounting or with a tool head mounting (without keyway). Therefore, no additional clamping accessories are required.

Our ATORN Disc Brushes are ideal for processing functional parts, such as sealing and contact surfaces, as well as for precise deburring, edge rounding, fine machining, and surface finishing of various components. Since the brushes are primarily used on stationary machines and in wet grinding, the use of coolant, water, or oil is recommended.

New Possibilities in Automated Finishing

Technical brushes are precision tools that are largely responsible for the quality of the finished products. They can be customized to almost any material to be processed, based on the part orientation.

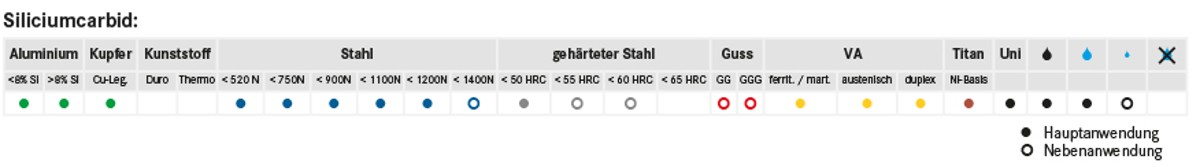

ATORN Disc Brushes offer a wide selection of abrasive bristles with silicon carbide or ceramic coatings in various grain sizes and filament diameters. The ATORN Disc Brushes are designed for direct adaptation to tool holders with tool head mounting (DIN 6357) and combination milling spindle mounting* (DIN 6358). As a result, they can be used on machining centers, CNC turning and milling machines, robotic cells, etc.

The brushes are used after the machining process and can be easily applied with the use of coolants, emulsions, or water. This allows the machined workpieces to be deburred and finished directly, securely, and reproducibly on the machine without the need for re-clamping.

The primary application of ATORN Disc Brushes is in precise deburring, edge rounding, and surface finishing of precision parts without altering the geometry of the workpiece.

Would you like more information about our ATORN Disc Brushes?

In our brochure "HIGHTECH DISC BRUSHES - For Automated Deburring," you will find everything you need to know.

Get informed now