Stainless steel machining – Tools for perfect machining

In common parlance, stainless steel is often ascribed rustproof properties. But are stainless steels actually always stainless?

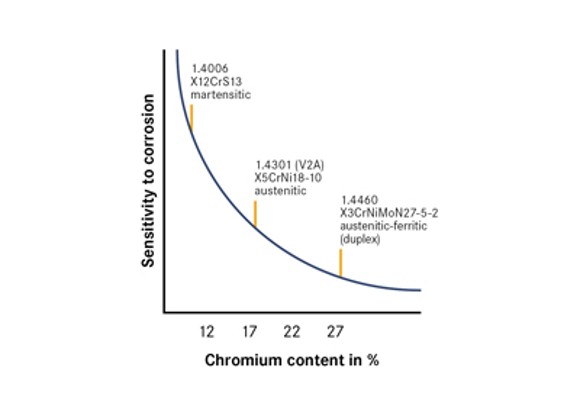

Unfortunately, this is not the case because, strictly speaking, the required properties only apply to the subgroup of stainless steels. Stainless steel is a steel of particular purity, which is defined in the EN 10020 standard. If stainless steel lacks chromium, it will rust just like conventional steel. A stainless steel only becomes a rust-resistant steel once it contains a certain amount of chromium.

Stainless steel: versatile and economical

Stainless steels can be found in a wide range of applications today. Over 50.9 million tons of stainless steel were produced worldwide in 2020 alone. Compared to many other materials, stainless steels are characterized by good corrosion-resistance that can withstand even mechanical or abrasive effects of action.

The requirements for stainless steels are a minimum of 10.5% chromium and a maximum of 1.2% carbon.

The high compressive strength and good toughness (even at low temperatures) make some of the stainless steels an optimal material in countless applications and industries. The challenge of machining them always remains the same: The material composition places extreme demands on the tool.

What stainless steels are there?

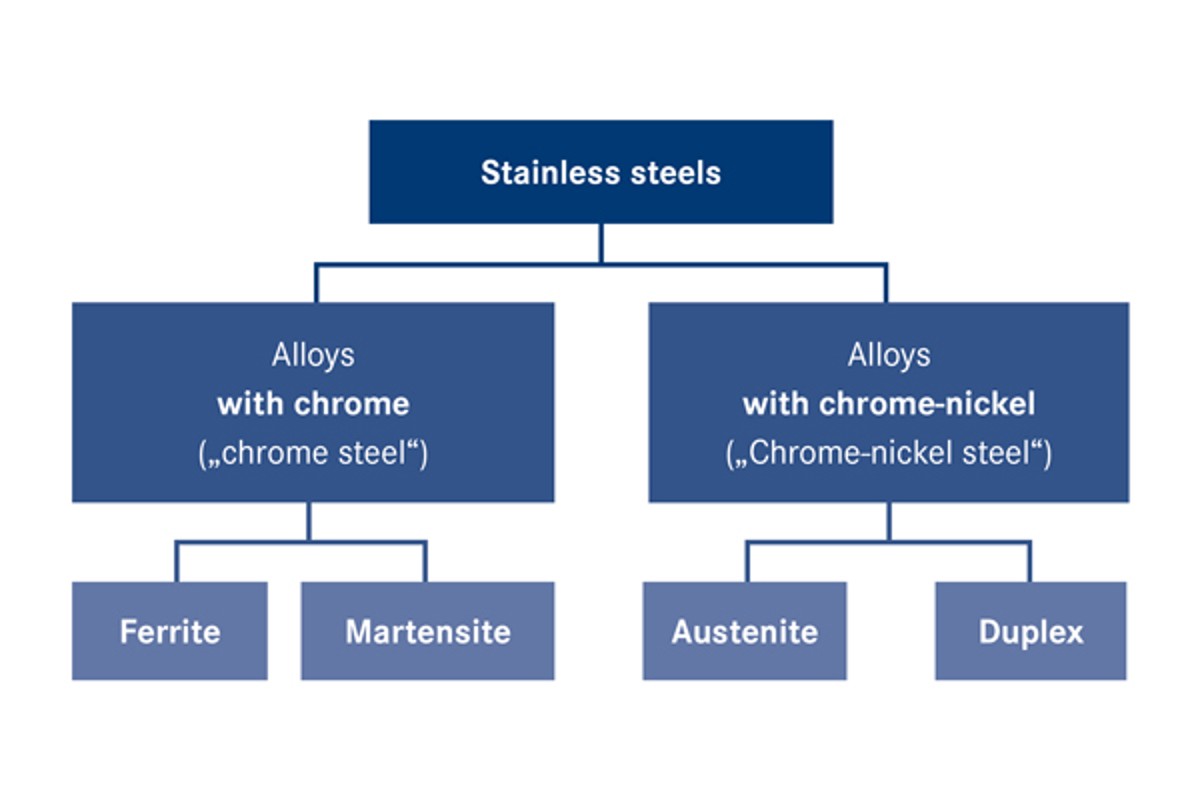

Stainless steels can be divided into four material groups based on their production and the resulting microstructure: Martensitic steels, ferritic steels, austenitic steels and duplex steels (also sometimes referred to as austenitic-ferritic).

These differ in terms of their mechanical and physical properties, corrosion resistance, workability and heat resistance.

From a metallurgical point of view, stainless steels are divided into chromium steel and chromium-nickel steel.

Alloys with chromium (chromium steel)

Martensitic stainless steels

Martensitic steels are very strong and brittle. They typically contain 12-18% chromium with a moderate carbon content.

Martensitic steels are generally extremely suitable for machining.

They are hardenable and more corrosion-resistant, have good chemical resistance, are wear-resistant and are easy to polish.

Advantages:

- High wear resistance and edge retention

- high strength, good formability

- Optimized corrosion-resistance

- high availability, internationally standardized

Application:

Knife industry, aviation industry and general mechanical engineering

Ferritic stainless steels

Ferritic stainless steels have a hardness of 60 HV and are therefore very soft. Common alloys contain 10.5-27 % chromium and a low proportion of carbon.

Ferritic stainless steels are extremely easy to machine and form and also have low thermal expansion. They are ferromagnetic in structure and therefore cannot be hardened by heat treatment. The ferritic microstructure also makes the stainless steel susceptible to corrosion.

Advantages:

- Good hot and cold formability

- high resistance to stress corrosion cracking

- good machinability

- low cost

Application:

Cooking utensils, kitchen construction, food industry, combustion plants and automotive, e.g. car exhaust systems

Alloys with chromium-nickel (chromium-nickel steel)

Austenitic stainless steels

Austenitic steels currently account for the largest share of stainless steel production. Their properties include excellent corrosion-resistance and good cold formability. They are non-magnetic at ambient temperature and cannot be hardened by heat treatment. Austenitic steels are characterized by medium to difficult machinability.

Advantages:

- Very good corrosion-resistance

- Very good hot and cold formability

- very good weldability

- low thermal conductivity

Application:

Chemical and petrochemical industry, shipbuilding, food industry, watch industry and medical technology, facade construction and roof construction

Duplex steels

Duplex steels are characterized by a combination of properties that correspond to a mixture of the properties of stainless chromium steels (ferritic and martensitic) and stainless chromium-nickel steels (austenitic). They have higher strengths than the stainless chromium-nickel steels, but have a higher formability than stainless chromium steels. Ferritic-austenitic steels are difficult to machine.

Advantages:

- very good corrosion-resistance

- good formability

- high notched impact strength

- good weldability

Application:

Pump rotors, stirrers, shafts and rollers for paper machines, oil, gas and petrochemical industry as well as on oil rigs

What actually makes stainless steel rust-resistant?

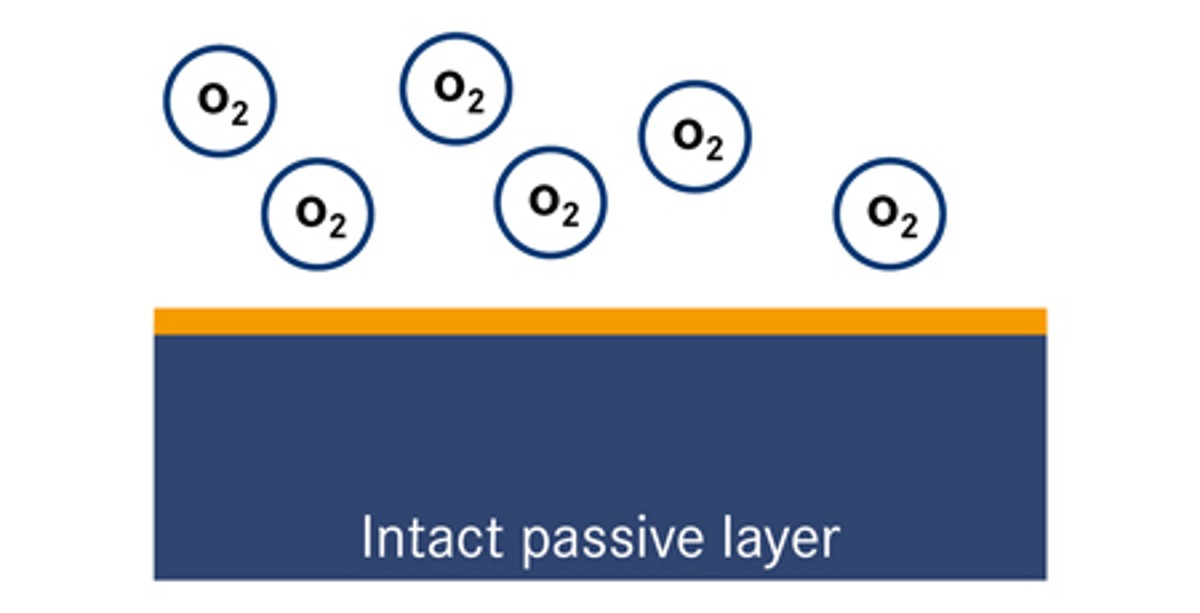

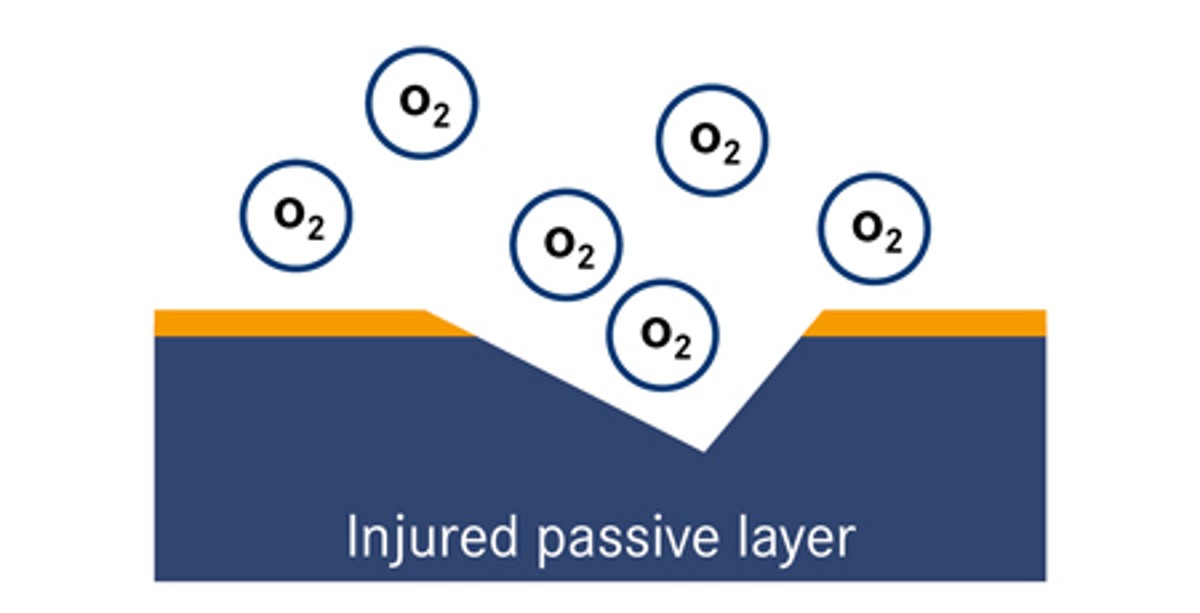

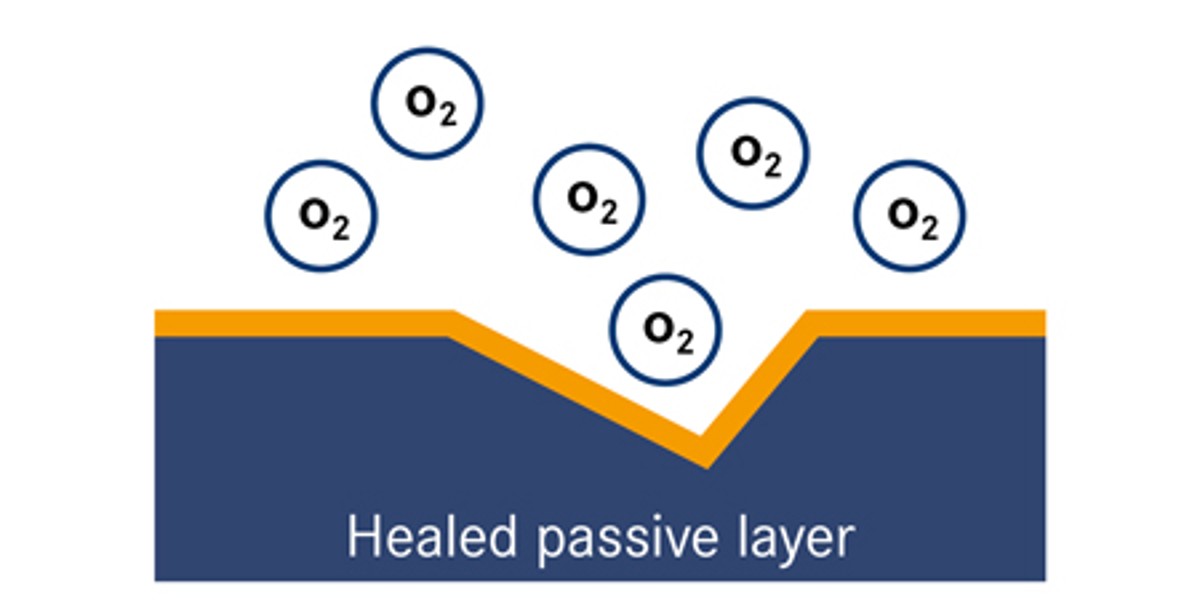

The chromium content of at least 10.5% in steel results in the formation of a passive layer, i.e. a protective layer of chromium oxide. The passive layer forms automatically under the influence of oxygen and thus protects the material from corrosion. If the layer is damaged, for example by scratches or machining, it automatically forms again. The functional principle is the same for all stainless steels: by increasing the amount of chromium and other alloying elements, the corrosion resistance becomes even more stable.

Intact passive layer

Injured passive layer

Healed passive layer

Which alloy components give which properties?

Steel properties are influenced by the manufacturing process and alloying elements, among other things. The various elements give the steel certain mechanical and chemical properties. But what properties are actually produced by chromium, nickel or molybdenum?

Do you still have questions about stainless steel processing or our tools?

Our experts will be happy to help you. Simply and conveniently send us your inquiry by e-mail.

Request now